OK so to start with I need to clean the boards with meth spirits

-probs use this on the hallway.

OR a 10-1 ratio of water to white vinegar – use this on the bedroom floors.

Try actually on sample pieces of wood.

The recommended sanding grit level is an important differential. Many hardwax oils specify a grit up to 150, including Fiddes, Rubio Monocoat and Saicos. Livos specifies 180 grit online but 240 on the side of the can, while Osmo specifies 240. Feast Watson and Odie’s Oil give no recommendations. Whittle Waxes also lists 150, but includes the phrase ‘or finer’ which is important as we shall see.

The sanding grit level profoundly affected surface quality (look and feel). Running my fingers along the length of eight samples – smooth to rough to smooth again – showed just how much the results were affected. Online forums are awash with questions like: ‘What happens if I sand to a finer grit?’

This question was asked of the suppliers and there were two common themes to the replies. First, there was no hesitation in recommending finer sandpaper to achieve a smoother result. But second, there is a limit to how fine one should go, because burnishing timber to extremes inhibits adhesion. A sanding range of 180–300 is my suggestion (species dependent).

FEAST WATSON – – can get at bunnings

https://shorturl.at/uu2zE

Punch exposed nails below the surface. Note that holes and

imperfections should be filled with timber putty after the first coat of

Timber Floor Wax to match the putty colour with the coated timber

colour.

Sand timber to an even, smooth surface. Vacuum and wipe to

remove dust.

Previously Coated Surfaces

Previous coatings need to be removed by sanding surface back to

bare timber.

Previous coatings of Timber Floor Wax or Floor Seal Oil can be

recoated without resanding.

APPLICATION

Surfaces to be coated must be dry and free from all dirt, dust, grease

or polish.

Timber Floor Wax should be stirred thoroughly before and during

application with a flat blade stirrer taking care not to introduce

bubbles.

Apply a coat of Timber Floor Wax to the timber with a brush, roller

or cloth. Ensure the surface is evenly covered.

Once first coat is thoroughly dry, any grain raise can be removed by

lightly sanding with 240 grit sandpaper, being careful not to sand

through the coating.

When the first coat is thoroughly dry. Apply a second coat of Timber

Floor Wax following the application process outlined above.

Do NOT apply in temperatures under 10°C or over 35°C.

FEAST WATSON TIMBER FLOOR WAX

MAINTAINANCE

Allow Timber Floor Wax to cure for a minimum of 4 weeks before

cleaning.

Regularly clean floors using Feast Watson Floorclean.

When the surface requires an additional coat, clean with Feast

Watson Floorclean and allow surface to dry fully. Apply one coat of

Timber Floor Wax as per application directions.

other flooring

https://woodemotions.pk/blogs/news/can-i-paint-over-epoxy?srsltid=AfmBOopL_PG0QTQO6w4NNjSIYjrQ8Oy4TvQ00AYQlNbHc8urTFl-B5TD

https://quicksandflooring.com.au/

-5 star google reviews also do replacement of floorboards, members of timber assoc etc

-neo

-five google stars: https://melbournedeckandfloorrestoration.com.au/

-prestige floors in melb

-total floors service

If you’re looking to retain the natural appearance of freshly sanded boards, pine or oak, Fiddes Hard Wax Oil Natural are both great products for defusing and countering the gold / orange colour you sometimes get.

- Fiddes Hard Wax Oil Natural also keeps wood looking as natural and unaltered in colour as possible and dries to a clear, satin-matt finish. It’s perfect for light coloured woods like pine, spruce and oak.

i want a hidden floorboard cavity ie this with a brass flush pull and maybe hinges maybe not to just get access to under house maybe in both bedrooms

flush pull for floorboard https://heritagebuilding.com.au/collections/flush-pulls-polished-brass

bhg.com/homekeeping/house-cleaning/surface/how-to-wax-hardwood-floors/

mopping liquid wax:

VACUUM HARD FLOOR MICROFIBRE MOP HEAD MIELE C3 Complete Cat & Dog PowerLine

not official miele attachment but could be worth it.

VARNISHES, POLISHES AND GRIME

Stripping back the layers of a very old timber floor without the aid of an industrial sanding machine can seem like an impossible task. But sanding is the harshest treatment you can submit a wooden floor to and it is a process that conservators will avoid where possible. Sanding destroys the invaluable patination that wood develops over years of wear. Preserving patination should be approached in the same way as with a fine piece of antique furniture. First, you must carefully strip back the layers of grime with turpentine and the delicate use of wire wool and a cabinet scraper. Then, once cleaned up, natural waxes should be used to enhance the natural colour and grain and to seal the aged wood. The choice of wax should always be dictated by the volume of traffic the floor will need to cope with. For high traffic areas, a floor polish with a high content of carnauba, a harder-wearing wax derived from the carnauba palm of Brazil, is the best option and should be mixed with a good quality beeswax. For lower traffic areas a good quality beeswax will suffice.

Lacquers and varnishes, which generally contain polyurethanes, tend to give the wood an orange, ‘plasticky’ appearance and should always be avoided on antique floors….

natural carnauba and beeswax polish from a specialist supplier is arguably the best solution for a heavily trafficked floor. Ideally, floors should be buffed weekly and polished thoroughly three times a year.

VICTORIAN TIMBER FLOORING (1837-1901)

Plain pine floors were used throughout most Victorian houses.

WOOD TYPE Pine used extensively throughout the period but the Arts & Crafts movement revived the passion for oak and gave rise to an interest in exotic hardwoods and maple. Well- chosen pine and fir planks were considered acceptable.

FIXING TYPE Tongue and groove fixing or facenailing were the norm.

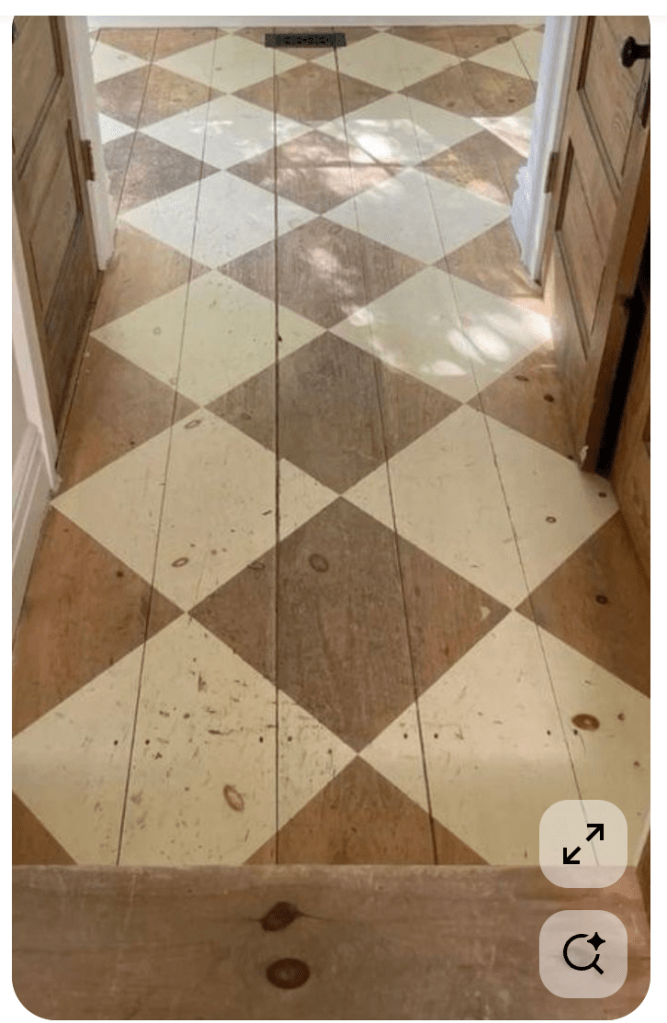

STYLE Pine floors were usually covered with rugs and the surrounds were stained and polished with beeswax and turpentine to create the effect of a better timber. Some borders were stencilled as an inexpensive alternative to parquetry. During the 1860s, floors painted in Indian reds and deep blues became fashionable. In Arts & Crafts buildings, the preferred wood, oak, was simply polished to enhance its natural beauty. The finest floors were cut from the full-width of tree trunks. The movement also created the trend for floors and wall panelling to be stained in similar dark tones. Staining, however, was reserved for inferior woods. In Art Nouveau interiors, carpets and rugs were considered the main decorative features so wood and parquet borders were polished to provide a simple. complementary back up. SOURCE: Timber Floors by Jasper Weldon, http://www.buildingconservation.com

NB the other thing is that when you’re polishing the floors with modern materials it can stop the floors from breathing and create new rising damp issues:

Changes to floor finishes may be enough to tip the balance towards too little evaporation. For example, an unfinished timber floor may be found to be cold and draughty in winter and so is modernised. Gaps beneath the skirtings are sealed with compressible foam; and new vinyl sheeting, or a polyurethane finish on the floorboards forms an effective seal, reducing previous circulation. New vents may be needed to restore adequate ventilation in this situation

-SOURCE Salt attack and rising damp: A guide to salt damp in historic and older buildings by David Young

Original pine flooring from the Victorian era was typically crafted from slow-grown Baltic pine, resulting in dense, durable boards with tight grain patterns. These floors were built to last, and with proper restoration and protection, they can continue serving for many more decades.

Beyond their practical value, well-restored pine flooring adds considerable charm and value to period properties. The wide boards showcase a quality of timber that’s increasingly rare in modern flooring, making their preservation particularly important.

Moreover, pine is particularly vulnerable to moisture damage and staining, which can lead to unsightly marks and even structural issues if left unprotected. This is where the choice of finish becomes critical – a high-quality, durable finish like Armourflex® Hard Wax Oil not only protects against these daily challenges but also maintains the wood’s natural ability to breathe while providing a protective barrier against spills and stains.

The finish needs to withstand years of use without degrading, peeling, or requiring complete refinishing, which would necessitate another round of intensive sanding and restoration. In heritage properties, where these floors represent both historical value and a significant financial investment, protecting them with a proper finish is not just about aesthetics – it’s about preserving an important architectural feature for future generations.

This premium finish stands apart through its unique formulation of natural soya oils, linseed oil from flax, and carnauba wax, creating a finish that penetrates deeply into the wood while forming a robust protective layer.

Unlike conventional varnishes that simply coat the surface, Armourflex’s microporous formula allows the wood to breathe naturally while providing exceptional resistance to water, stains, and daily wear.

This breathability is particularly crucial for period pine flooring, helping to prevent moisture-related issues that can compromise the wood’s integrity. The finish is remarkably versatile, available in both matt and satin finishes to suit various interior styles, and is certified Food and Toy Safe when dry to EN 1186:2002 & EN71:3 standards.

What truly sets Armourflex® apart for flooring applications is its outstanding repairability – unlike traditional finishes that require complete sanding and refinishing when damaged, Armourflex® can be spot-repaired easily in high-traffic areas, saving time and preserving the original restoration work.

The quick four-hour drying time means rooms can be back in use sooner, while the finish’s durability ensures long-lasting protection that maintains the natural beauty and character of Victorian pine flooring. For heritage properties where authenticity is paramount, Armourflex® brings out the beauty in the wood’s natural colour and grain patterns rather than masking it.